Design and build specialist, JBA Bentley, has secured a £19m contract to deliver civil flood alleviation works at Sheffield Forgemasters’ Brightside Lane site.

The civil engineering project will intercept the Lower Don Valley’s Bagley Brook culvert where it enters Sheffield Forgemasters’ site, allowing storm water to be diverted, stored and transferred into the River Don.

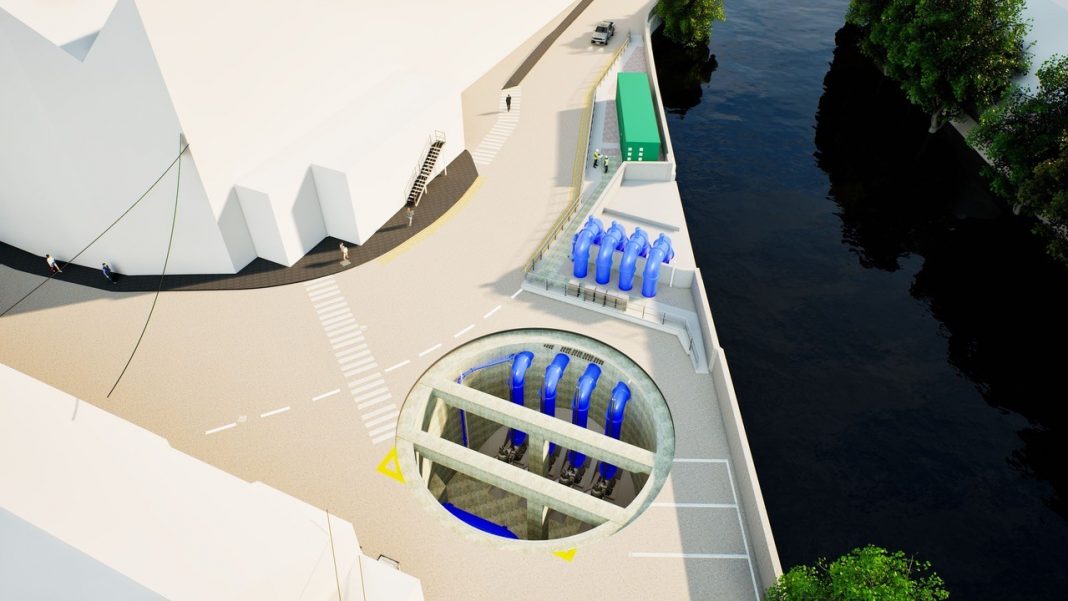

A large underground catchment system consisting of storage tanks, a cross-site transfer tunnel and pumping station, will allow large volumes of water to be re-routed and contained at critical periods, to be released back into the river at a controlled flow-rate.

Craig Fisher, programmes director at Sheffield Forgemasters, said: “We have already made huge steps towards flood prevention on the site, but the Bagley Brook transfer system will address a known flood-risk which can affect both our plant, and this part of the city.

“The brook, which runs through an enclosed culvert along our northern boundary and into the River Don, was contained in the Victorian era and the culvert simply can’t cope with an excessive flow of water, causing it to breach in heavy storm conditions.

“The new transfer system will allow storm water to be diverted from the culvert and contained in large attenuation tanks, before being transferred to the River Don via a new underground pumping station, near to Abyssinia Bridge.”

Graham Frudd, contracts manager at JBA Bentley, said: “We are delighted to be working with Sheffield Forgemasters on what is a major flood alleviation project in the Lower Don Valley.

“JBA Bentley will undertake construction of a new weir chamber, integrated into the side of the existing Bagley Brook culvert, to allow a proportion of storm water to be redirected from the Bagley Brook culvert to a new pumping station at the side of the River Don.

“This will involve sinking a five-metre shaft to receive a tunnel boring machine which will drive a tunnel, twelve metres deep, for 320 metres across Brightside Lane. This will be launched from the 15m diameter shaft which will double as storage and a pumping station.”

A section of flood wall at Sheffield Forgemasters’ boundary with the Don will be repositioned to accommodate a new outfall structure from which the pumping station will discharge storm water back into the river at a rate of 8,000 litres per second.

The two-year flood alleviation works form part of Sheffield Forgemasters’ planning requirements for its new 13,000 tonne Forging Line, which is currently under construction adjacent to the Midland Mainline railway.