The University of Sheffield has joined a £38 million UK aerospace programme designed to industrialise additive manufacturing and reduce production costs. The four-year initiative, known as Digitally Enabled Competitive & Sustainable Additive Manufacturing (DECSAM), is led by Airbus and supported by Innovate UK, the Aerospace Technology Institute and the Department for Business and Trade.

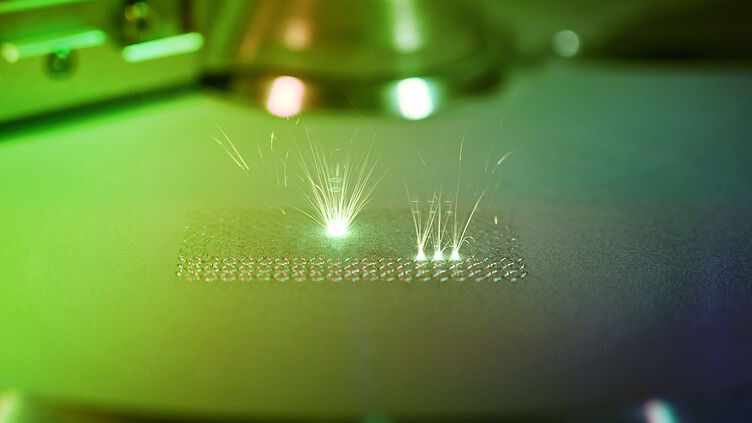

The project will develop advanced laser powder bed fusion processes using technologies such as beam shaping and real-time process monitoring to increase manufacturing efficiency and reduce waste. It will run until June 2028 and aims to establish a digitally connected supply chain for flight-ready metal components.

Eleven organisations are participating in the collaboration, including Airbus, Renishaw, ASTM International UK, Authentise, GKN Aerospace, The Manufacturing Technology Centre, Additive Manufacturing Solutions, APEX Additive Technologies, Domin, ToffeeX and the University of Sheffield. Together they represent the UK’s full additive manufacturing value chain, from materials development to final part qualification.

As the sole academic partner, this project highlights the University of Sheffield’s leading expertise in additive manufacturing and computational modelling. This cross-cutting research project will allow us to accelerate our work in advanced manufacturing and computation modelling, bringing together diverse areas of expertise that wouldn’t otherwise be possible at this speed. The additive manufacturing research we’ll be conducting at the Henry Royce Institute will not only contribute to their key performance indicators but also directly support two of our university’s spin-out companies: Instruct3D and m2i2. We’re especially excited about the potential for this research to integrate directly with the AMRC’s Factory+ connected manufacturing framework,” said Prof. Iain Todd, Professor of Metallurgy and Materials Processing at the University of Sheffield.

The programme is focused on improving alloy performance, automating production, developing scalable factory models and validating recycled material routes. Sheffield’s involvement will draw on the Henry Royce Institute for Advanced Metals Processing, applying modelling and simulation research to enhance machine control and process validation through to December 2027.