Private equity firm acquires gear systems specialist

Private equity firm Stellex Capital Management, has acquired gear systems specialist, David Brown Santasalo (DBS) from private equity firm, N4 Partners.

David Brown Santasalo is a Huddersfield-headquartered business delivering engineered industrial gear systems and services, manufactured for critical industrial applications including Mining & Minerals, Fibre & Paper, Power Generation, Cement, Oil & Gas, Defence and more. The organisation has 26 locations, spanning six continents worldwide and employs more than 1,100 people.

Keith Mitchell, David Brown Santasalo chairman and partner at N4, said: “N4 is pleased to announce the successful exit of DBS to Stellex. We have valued our strong working relationship with the DBS management team and have been delighted to see the business deliver profitable growth in recent years.

“On the back of multi-year contract awards and strong growth in the order book across all business units, a transformational investment programme has been completed which has significantly upgraded key capabilities across the business’s global footprint. DBS has a fantastic platform to deliver further strong growth and we wish the business and its new owners every success.”

David Armitt, Chief Executive Officer at David Brown Santasalo, said: “On behalf of David Brown Santasalo, we are very pleased to have secured this investment by Stellex. They have experience investing in our sectors, have spent time working with us on our plans, and clearly see the potential of DBS to further develop our services for customers. I look forward to this new chapter in which we can continue to strengthen our position in the market.”

Karthik Achar, partner at Stellex Capital Management, said: “We are excited to welcome David Brown Santasalo into the Stellex portfolio of investments. DBS brings global delivery of gear manufacturing and service expertise within a broad range of critical service sectors, and with many long-term relationships. We look forward to working with the management team and its employees as we strive to deliver growth and build on the company’s successes into the future.”

Levelling-up cash to create children’s science and technology centre in Scunthorpe

A new science and technology centre for children and families will be created in Scunthorpe with £2.5m Government levelling-up cash confirmed.

Repairs to the walls, roof and exterior of St John’s Church will mean the whole building will become accessible and connected to the recently developed gardens in Church Square.

The creation of the even larger space for events and activities paves the way for ‘Discover@20-21’ a new centre where children and families will experience interactive science and technology activities – adding to the award-winning arts and heritage exhibitions.

Cllr Rob Waltham, leader, North Lincolnshire Council, said: “This work will restore one of our key heritage sites and a notable local landmark. It will be fantastic to see the hoardings finally come down and open this space up further for community events.

“This is the latest part of our plans which have been backed by millions of pounds of Government cash, everything is designed around creating a new, different future for Scunthorpe town centre – the science and technology centre will be a major addition to Scunthorpe.

“We must create more reasons to come into town so people can have different experiences and leisure activities. That is what we are doing to create a new, modern, thriving place and the Government has shown its confidence in these projects with hard cash.”

The plans will be developed further if the council gets Listed Planning Consent. Included will be further development of the park and gardens, extending the wildlife haven in the heart of the town, expanding the space for families and nearby school children and connecting the venue to the outdoor space.

The church will also have a new eco-friendly climate control system installed opening the door to new exhibitions and displays.

This latest development is at the heart of a raft of schemes designed to radically transform the town centre by bringing more businesses and jobs, new homes and a rich cultural quarter using cash from the Towns Fund.

Holly Mumby-Croft, MP for Scunthorpe, is vice chair of the Towns Fund Board. She said: “There is no doubt that traders in high streets up and down the country are fighting hard to be part of a new future.

“These latest plans will reshape the experience people can have in the heart of the town, there will be more reasons for people to come along and that will mean more people shopping and spending money with local traders.

“The cash from Government is being used to develop a range of projects that connect people – physically and virtually – to jobs, culture, leisure and retail. It’s really exciting and I am looking forward to seeing the church transformed and a new science and technology centre developed.”

This latest cash is just part of the more than £80m of Government funding which has backed the council’s plans for creating a new future in North Lincolnshire. This includes cash for roads, new motorway junctions, enabling people to develop their skills and supporting communities.

Cash from the Towns Fund, Future High Streets, Levelling-Up, UK Shared Prosperity and through other Government departments comes alongside £75m for a new port development, £5m for the A15 enhancements, investment in the new university campus, tens of millions for education and the £200m plus paid to support jobs throughout the pandemic.

British Steel works closer to sustainability targets

British Steel has launched its first Decarbonisation Action Report, exploring the progress made towards sustainability goals and providing clarity on the true measurement of the carbon impact arising from its products.

The report highlights a commitment to setting company-wide emission reductions in line with the Science Based Targets initiative, as well as ongoing feasibility studies on integrating Electric Arc Furnace steelmaking into existing operations.

Ben Cunliffe, Commercial Director, Construction, said: “Our commitment to a carbon intensity saving of 82% by 2035 and to net zero by 2050 represents one of the most significant decarbonisation projects across the whole of the UK national interest.

“This report looks at why buying British provides huge economic value to the UK in terms of both jobs and billions of pounds of Gross Value Added. In stark contrast, importing steel not only supports industries and economies outside the UK, it also generates significantly greater emissions through the transportation process.”

The report shows how steel imported into the UK generates up to 24 times greater emissions arising from transport of regular imports into the UK.

Ben said: “The UK construction sector is moving at an increasing pace towards sustainability and, equally, British Steel is undergoing an exciting transition to achieve our ambitious targets. We’re very much looking forward to working closely with both our customers and the supply chain to support this.”

£30k fine for dental supply company after explosion of flammable liquid

A dental supply company has been fined £30k after an explosion of flammable liquid led to a fire at its premises in Halifax.

John Winters & Company Limited pleaded guilty to safety breaches after one of its employees was put at serious risk in the explosion that led to flames ripping through the building.

Leeds Magistrates’ Court heard that, on 23rd April 2021, the worker had been decanting heptane from a metal drum into a plastic bulk container. Other employees were also put at risk when the explosion resulted in a fire spreading rapidly throughout other production buildings. Nobody was physically injured in the fire which was tackled by more than 60 firefighters at its height.

An investigation by the Health and Safety Executive (HSE) found that the decanting of flammables had been unsafely undertaken at the company for several years despite well-known industry guidance.

The splash filling of Heptane generated a static charge creating a spark which caused an explosion during the decanting process, flammable material then spread further as there were no containment measures. The poor practice of storing cardboard boxes nearby fuelled the fire allowing it to spread significantly.

John Winters & Company Limited of Washer Lane, Halifax, West Yorkshire pleaded guilty to breaching Section 2 (1) of the Health & Safety at Work etc Act 1974. The company has been fined £30,000 and ordered to pay £8,030.94 in costs.

After the hearing, HSE inspector Andrea Jones said: “Implementing appropriate control measures when handling flammable liquids is essential to prevent the generation of a static charge that can result in explosions and fires.

“The incident could so easily have been avoided by preventing splash filling, introducing appropriate earthing and bonding systems, training and supervision.

“HSE has well known guidance to help companies to understand what’s needed.”

Late payments stifling small businesses

The Federation of Small Businesses (FSB) has released a report that uncovers the true scale of damage caused by the late payments crisis as entrepreneurs say: “enough is enough.”

Time is Money: The Case for Late Payment Reform, exposes the insufficient measures in place to hold big businesses to account and calls for a level playing field for smaller firms.

This comes alongside a Department for Business and Trade (DBT) prompt payment and cash flow review, which ends in Spring, and looks at improving arrangements to support small businesses experiencing difficult payment practices.

Findings include on average through 2022, quarter-on-quarter:

- 52% experienced late payment.

- 25% reported increased late payment.

- The most affected sectors include education, construction, administrative, professional, scientific, transportation, IT, arts and human health and social work.

- Small businesses in south-east and east of England, and Northern Ireland were more likely to experience late payments.

- 37% of applied for credit to manage their cashflow.

- 62% of the British public say businesses should be paid within a week.

- 55% of the British public would support more controls.

- Give audit committees of large firms oversight of payment practices and reporting on progress in their annual report.

- Publicly commit to limit the maximum payment terms to small suppliers in law by 2027 if the situation does not improve.

- Bar late payers from public procurement contracts.

- Impose 30-day payment terms, which should be a maximum throughout supply chains.

- Mandate the Small Business Commissioner to investigate potential instances of poor payment proactively, instead of only when a complaint has been made.

- Make the Prompt Payment Code (PPC) mandatory for all local authorities.

- Create a new local authorities Payment Practice League Table with financial incentives for those at the top and bottom for England.

New housing development in the centre of Grimsby takes a step forward

Proposals for a new housing development in the centre of Grimsby will be taken forward following a North East Lincolnshire Council Cabinet meeting.

The Town Centre Masterplan identified the Alexandra Dock area as a major asset for Grimsby, with significant potential for it to be used in a more intensive way, including development of a major residential district, which takes advantage of access to the water space and key improvements to the nearby spaces and facilities available.

Brownfield land near Alexandra Dock was identified in the Grimsby Town Centre Masterplan as a key area that could be used to generate that new housing stock.

Cllr Philip Jackson, leader of the council, said: “Our main objective of this work is to create a place that connects the town and its community with its waterside, creating a fantastic urban living environment that’s kind to the planet.

“There’s a long way to go yet, and developments of this scale don’t happen overnight. We are working to improve the town centre as a whole, including increasing the leisure offer with our redevelopment of the western end of Freshney Place, and, through other Towns Fund projects, changing how the town is used as a whole.”

The first housing phase is proposed to be the site behind the Onside Youth Zone, accessible from Fisherman’s Wharf. The area was put forward, and formed part of, the Towns Fund projects that were agreed with Government in 2020/21.

Significant recent work has been done with Homes England to consider how the opportunities for the area might be taken forward. The council has managed to secure funding from Homes England, which has funded initial studies into the potential regeneration of Alexandra Dock.

Further discussions are ongoing to try to secure additional funding for initial technical studies required to progress the plans for the area, and to start the procurement of a development partner to work with the council on this scheme.

Alongside this, it’s planned to submit a bid to the Brownfield Land Release Fund, administered by One Public Estate (a locally-led partnership in partnership with DLUHC, funding works to regenerate public sector owned land and buildings). If secured, this money would increase the available budget to help deliver higher quality ultra-low-carbon homes.

Some initial land remediation work will be done this year to begin preparing the site for future phases of the work. Public will be able to have their say about the plans as the project develops.

Hauliers give back to community by inviting students to see the company in action

Students from Horizon Community College have been given an insight into the world of work by spending time at at Stanton Logistics in Goldthorpe.

Seeing the enthusiasm and interest during mock interviews and a Q&A at Horizon, co-founder and MD Chris McGinleyinvited some of the students to visit the Goldthorpe site for a morning earlier this month to show them how the business operates.

They got to sit in on operations meetings with directors and senior managers before being split into groups to learn more about the different aspects of the business, as well as receiving a full tour of the site and warehouse.

The visit was enjoyed by everyone, and Chris has been asked to sit on the panel for business presentations by more students at Horizon in the future.

Councillor Robert Frost, Cabinet spokesperson for Regeneration and Culture, said: “It’s fantastic to see a local business giving back to our young people. It’s important that our students see a variety of career pathways for themselves in Barnsley for when they leave college, whether it’s as a part of someone else’s business or by starting one of their own.

“My thanks go to Chris and the team at Stanton Logistics for facilitating this magnificent opportunity.”

Chris added: “Having the boys visit us for the morning was a brilliant success and I hope they enjoyed their time with us.

“For me, it is about giving back to the community and encouraging students to work hard and be regular attenders at school, dovetailing that into the work environment when school life comes to an end and the importance of ‘turning up’ becomes even more relevant.

“My message to them is to find your thing in life and pursue it with energy and consistency as money then becomes a by-product of enjoying yourself.

“I came from a very working-class background of steelworkers and started with £6,000, which now has turned into a multi-million pound group of businesses. Anything really is possible. I’ve proved that and continue to progress my businesses as I reach the age of 50 this year.”

Green light for Lincolnshire college’s new learning centre

A new bespoke learning centre for young people and adults studying at Boston College has been given the go-ahead – following support by planning experts at Marrons.

The two-storey Mayflower building – which is one of the Boston Town Deal projects – will provide high-quality further education training facilities alongside public access spaces, including a cafe, restaurant, and hair and beauty salon, which will be managed by the college and staffed by students to provide real work experience opportunities.

It will also include exhibition and events spaces, a digital hub, business incubation units for local start-up companies, conference facilities and meetings rooms, and 74 car and 60 bicycle parking spaces.

Claire Foster, Boston College principal and CEO said: “We are thrilled that planning permission for the iconic Mayflower, the flagship project of Boston’s Town Deal fund, has been granted. The state-of-the-art facility will provide a shining beacon of aspiration for higher level and adult education at a time when our town needs it most.”

The existing Ingelow Centre will be demolished to make way for the 1,940sqm building. The site, which was previously a care home, was acquired by Boston College to house its foundation learners, who will be moving into a newly-refurbished building based on the main Rochford Campus.

Jacqueline Jackson, planning director at Marrons, said: “The unique Mayflower building will provide facilities not currently available within Boston, enabling businesses and learners to connect, create and innovate together, and acting as a catalyst to drive forward significant economic growth.

“It is great that were able to deliver permission promptly to enable the development to progress quickly, especially because the multi-functioning space will make a big difference to the everyday life of the local community. We look forward to seeing it complete and the high-quality facility welcoming students and businesses alike.”

The Mayflower is benefitting from £10 million in Towns Fund investment.

Neil Kempster, chair of Boston Town Deal, said: “It is fantastic news that planning consent has been granted for the Mayflower. This is a significant step towards creating a new, inspirational centre for learning in Boston.

“The Mayflower project has always been the flagship scheme within the Town Deal portfolio and it is brilliant news that it has taken a massive step forward with the grant of planning permission. We look forward to continuing to work with Boston College as they bring this important project to fruition, which will provide many more opportunities for local people to gain skills, knowledge and training.”

The project is part of a wider proposal that will deliver a high-quality public realm linking the Mayflower building the redevelopment of the adjacent leisure centre.

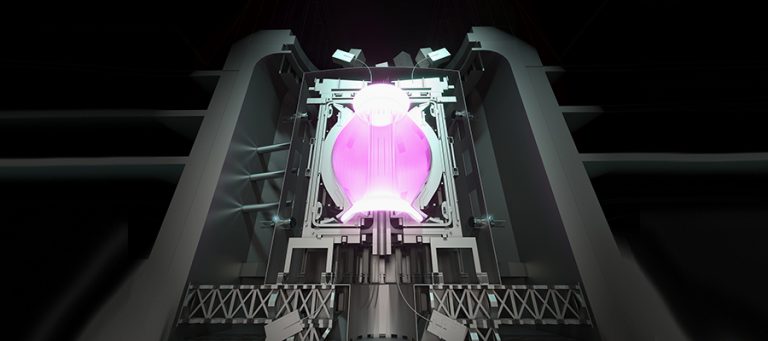

University of Sheffield to work in partnership with UKAEA on fusion energy project

The United Kingdom Atomic Energy Authority and the University of Sheffield will work in partnership to drive the development of fusion technology and the UK’s future fusion industry.

The collaboration will see the University of Sheffield appoint two chairs in fusion research and development, and establish new research programmes to address global fusion challenges:

- The Chair in Qualification for Fusion will address fundamental engineering challenges in the qualification of components, fabricated assemblies and systems for use within future fusion power plants.

- The Chair in Fusion Materials will focus on innovation in materials design and processing to improve power plant performance and the decommissioning and recycling of new materials.

Battery company recruits production teams for South Yorkshire manufacturing facility

The Ultimate Battery Co has started producing batteries at its site at Thurcfroft in South Yorkshire with the first products being dispatched this month.

It’s making starter, lighter, and ignition batteries for vehicles, and hopes to be employing 500 skilled workers by 2026.

A recruitment drive is under way for various roles in the first of a series of production teams, and recruitment will continue over the forthcoming months as production ramps up.

Maurizio Cunningham Brown, Founder and Global CEO of UBC, said: “The site at Thurcroft is the ideal location for our first facility. It combines the benefits of local industry knowledge, good transport links, and a strong workforce ethic. It is close to our research partnership with the AMRC and The University of Bradford, as well as strongly supporting the commitment from the South Yorkshire MCA to net zero manufacturing. It is a quantum leap for the company and will support the government’s objectives to achieve net zero and reduce dependence on fossil fuels.”

Production of UBC’s patented and cutting-edge battery modules has started, with the first order being dispatched in March 2023. Currently, the company is making substantial investment in the site to create a state-of-the-art facility. This includes the evaluation and installation of renewable energy solutions. Additionally, UBC have begun their next round of funding.

The batteries it makes are lighter and more energy dense than other types, using the company’s own Duophasic technology, involving a modular design making the battery suitable for vehicles of all sizes, from electric scooters to trains and planes.

UBC’s = battery products are designed for a sustainable economy. Locally-sourced materials with a high recycled content are used and, at end of life, up to 95% of material is recovered for re-use. The manufacturing process uses innovative techniques to ensure quality and minimise waste. UBC will make use of renewable energy generation across the operations to minimise carbon footprint.

The new Thurcroft site will also house UBC’s innovation hub team of scientists and engineers, who will focus on bringing the advantages of UBC revolutionary technology into the development of the next generation of power trains for electric vehicles. A key part of the innovation hub will be the rapid prototype centre, reducing product development time from years to weeks for new battery applications.