Walther Strong expands to Grantham industrial estate

British Gypsum supports inmate rehabilitation with donation to Willmott Dixon programme at HMP Lincoln

The programme, aimed at imparting drylining skills to inmates, not only equips them with valuable trade skills but also paves the way for successful reintegration into society.

In an ongoing commitment to uplifting local communities, British Gypsum has donated essential materials for the Willmott Dixon initiative at HMP Lincoln. The donation includes British Gypsum Plasterboard, timber sole plates, various screws, studs, and fixing straps, all of which are integral to the drylining training program. The Drylining Academy is instrumental in providing inmates with a unique opportunity for personal growth and skill development. By participating in the drylining training program, inmates not only gain a valuable trade skill but also earn qualifications that significantly enhance their employability upon release. “The donation to the Drylining Academy exemplifies our shared commitment to community well-being and sustainable rehabilitation,” said Sam Blacknell, head of skills partnership at British Gypsum. “We are honoured to contribute to a programme that empowers inmates with skills and knowledge, offering them a chance to rebuild their lives and embark on a new path of success and independence.” The Willmott Dixon drylining training programme aligns seamlessly with HMP Lincoln’s mission to promote inmate rehabilitation and reintegration. With the unique ability to provide inmates with training, testing, and CSCS card certification within the facility, HMP Lincoln is a pioneer in preparing inmates for a smooth transition back into society and offering them a specialised skill set that opens doors to various employment opportunities. Shelley Williamson, social value manager at Willmott Dixon, said: “We are deeply committed to driving sustainable change through our initiatives. The partnership with British Gypsum is a testament to our shared dedication to social impact and redefining the lives of individuals within our communities.”ABBA’s Björn to speak at Business day event in Bridlington

Driffield firm opens distribution centre in the Netherlands

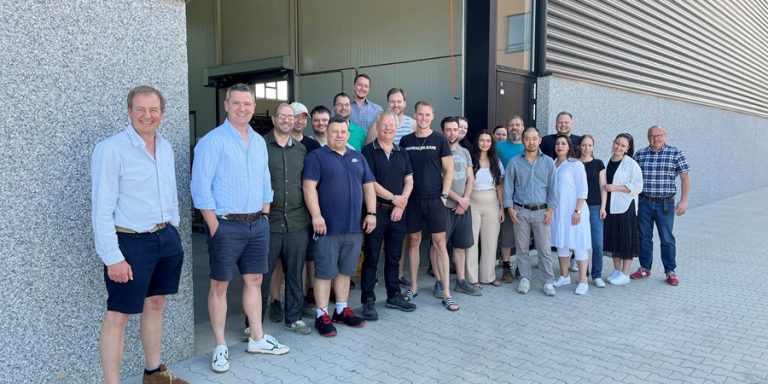

Driffield-based wellness business Vyta Health has opened a new distribution centre in the Netherlands.

The custom-built distribution centre boasts more than 1,600 sqm of warehouse and office space for the 26 employees based there. This expansion now gives Vyta Health nearly 5,000 sqm of distribution space across the UK and Europe, with a team of 43 employees. Vyta Health specialises in importing premium vitamins and supplements from the US, and distributing them across Europe. The Group rebranded as Vyta Health at the start of the year, merging two leading supplement businesses, Bigvits and By Nature. Group CEO Will Brennand said: “The distribution centre will allow us to further scale and streamline our operations in the Netherlands, and service our many trade and retail customers as we continue to expand across Europe. The new site has been in the pipeline since we acquired By Nature 2 years ago and we are all really excited to open its doors. The move supports our aim to become the largest independent distributor of vitamins and supplements across Europe.” Operations Director Sascha Gerdowski added: “We worked closely with the developers to ensure the new building would meet our needs as we continue to grow, and we are delighted with the outcome. We have even included a cool room to ensure products can be stored at the right temperature all year round, to maintain their high quality. We are really proud to finally move into the new distribution centre which will help us deliver our Group strategy in the years to come.”Forgemasters signs MoU to be part of UK nuclear reactor development

Jasper joins Banks Long & Co as Graduate Surveyor

West Burton Energy takes on green energy storage plant project

Couple launch new health facility in Gainsborough

Clegg Construction appointed on multi-million-pound hotel refurb in Leeds

Contractor Clegg Construction has been appointed to deliver a multi-million-pound refurbishment at the Cosmopolitan Hotel in Leeds.

Work has just started on site at the prominent hotel on the corner of Lower Briggate and Swinegate, which will be operated by Belfont Hotels.

The design and build project will modernise the building and includes the refurbishment of existing bedrooms, as well as creating new bedrooms, to take the total number of guest rooms to 108. It also involves modernising ground floor function rooms, the restaurant and bar, as well as the installation of new windows and renovations to the roof and elevations.

Clegg Construction pre-construction director, Ross Crowcroft, said: “We are very pleased to have started on site to refurbish and modernise one of the most iconic hotels in Leeds city centre.

“This refurbishment of the Cosmopolitan Hotel for Belfont Hotels will upgrade a landmark building in the heart of Leeds and turn it into a leading hospitality venue which will be perfect for both leisure and corporate demand.

“Clegg Construction is extremely familiar with the area around The Cosmopolitan Hotel, as we are currently on site at Spinners Yard in Regent Street delivering a 185-apartment private rented scheme for Rise Homes, plus we are working on an 11-storey student accommodation development in Leylands Road.”

Other members of the development team include project manager Edmond Shipway, architect Franklin Ellis and engineer Rodgers Leask.

Work is expected to be completed in the spring of 2025.

Keval Thakerar and Akshay Dhamecha, directors at Belfont Hotels, said: “We are excited to be working with Clegg Construction on this refurbishment that will see the Cosmopolitan Hotel repositioned as one of Leeds City Centre’s leading hotels, benefitting the local economy and community.”