Rotherham’s Nuclear AMRC is working with engineers from South Africa and America to develop a new weld repair technique to meet quality requirements for safety-critical fabrications.

The research involves WeldCore technology developed for the power generation and petrochemical industries by eNtsa, an engineering technology institute based at Nelson Mandela University in South Africa.

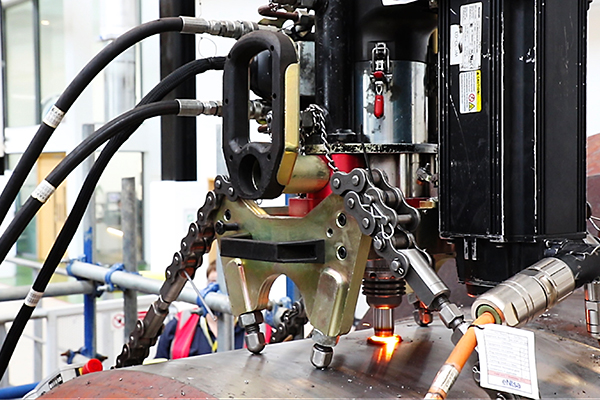

WeldCore was developed to cut core samples for material analysis from high-pressure components such as steam pipes, and uses a solid-state welding technique known as friction tapered hydro pillar processing (FTHPP) to permanently plug the hole and allow the component to remain in operation.

The Nuclear AMRC has been developing electron beam welding techniques for reactor pressure vessels since 2018, in an ongoing collaboration with US-based research institute EPRI. The team have successfully demonstrated how electron beam welding can help slash the production time and cost of reactor pressure vessels for a new generation of small modular reactor (SMR), by replacing multiple arc welded passes with a single deep-penetration power beam weld.

But as in any welding process, there’s always the risk of a defect which could lead to significant costs and delays, or even the scrapping of the entire fabrication. Before the process can be used in the nuclear sector, there must be a proven method for repairing such flaws.

Will Kyffin, head of welding and materials at the Nuclear AMRC, said: “Codes and standards require you to have an effective repair strategy in place. This work is addressing one of the most severe types of flaw, where the electron beam welding process can’t be used to repair the flaw itself.”